Eliminating oxygen from the food’s atmosphere in the packaging usually means the products’s spoilage course of action is noticeably delayed. Oxygen will allow food to decay by creating a helpful, hospitable atmosphere for microorganisms.

Powder filling machines are meant to properly and competently fill containers with many sorts of powders, including pharmaceutical dry powder, food additives, substances, and powdered beverages.

I have been making use of Foodsaver type vacuum sealers For several years. I've normally wanted a chamber vacuum machine but the price was difficult to justify. After i viewed the YouTube movies around the Vevor and observed the sensible cost I made a decision to acquire a single. I am very pleased with my new machine. Placing it up was easy and easy And that i utilized a few of the high priced air channel luggage I had on hand to test sealing unique things.

Beauty manufacturers count on liquid packaging machines to fill perfumes, lotions, gels, and creams. Consistency in fill ranges is critical in cosmetics to take care of manufacturer standing and shopper fulfillment.

Powders are categorised into two groups, totally free flow like granulated sugar and non-free of charge flow which include flour. Our powder packaging machinery can cope with equally different types of powder. Where demanded, we provide a changeover package totally free circulation and non-no cost stream powders. Powder lines generally have blended ingredients such as ingesting chocolate.

The P5-4ZA can be customized on your unique packaging line format and integrated with a variety of solutions and elements to create a totally turnkey packaging line. Point Five Packaging will assist you by conceptualizing, building and establishing infeed and outfeed conveyor traces, tray denesters, fillers and depositors, markers/printing machines, aligning gadgets, etc.

Powder machines for filling are created to automate the process of filling powdered items into containers, getting rid of the necessity for handbook labor.

Sealing good quality – Inspect seal power, gaps and beauty enchantment on random pouches from generation runs.

How Liquid Packaging Machine Price can Food Packaging Machines Enhance Performance Food packaging machines enrich effectiveness by automating repetitive tasks, therefore lowering enough time and labor expenditures linked to manual procedures. These machines boost precision in packaging by persistently measuring and dispensing exact amounts, reducing waste. Additionally they enable superior-speed operations, which ends up in elevated manufacturing output and more rapidly turnaround periods.

By weighing these components, firms may make an knowledgeable conclusion that aligns with their operational plans and shopper anticipations.

Automatic packaging methods give various pros. They increase efficiency by rising packaging velocity and minimizing human mistake. These techniques be certain regularity, providing uniform packaging that fulfills quality criteria. By decreasing the need for guide labor, companies conserve on operational fees.

Streamline your system connections making use of 1 common set of parameters, with no need to have for additional equipment.

With the velocity of a packaging machine in food and beverage options to your precision of a filling machine in prescribed drugs, the flexibility of such machines serves a great number of apps.

Standard maintenance is important to maintain liquid packaging machines operating efficiently. Responsibilities like cleansing nozzles, examining sensors, and lubricating moving areas support stop breakdowns and assure consistent functionality.

Amanda Bearse Then & Now!

Amanda Bearse Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! Mary Beth McDonough Then & Now!

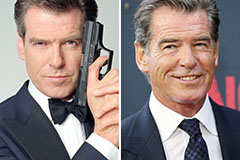

Mary Beth McDonough Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!